DEFECTIVE PRODUCT DETECTION

Defective Product Detection

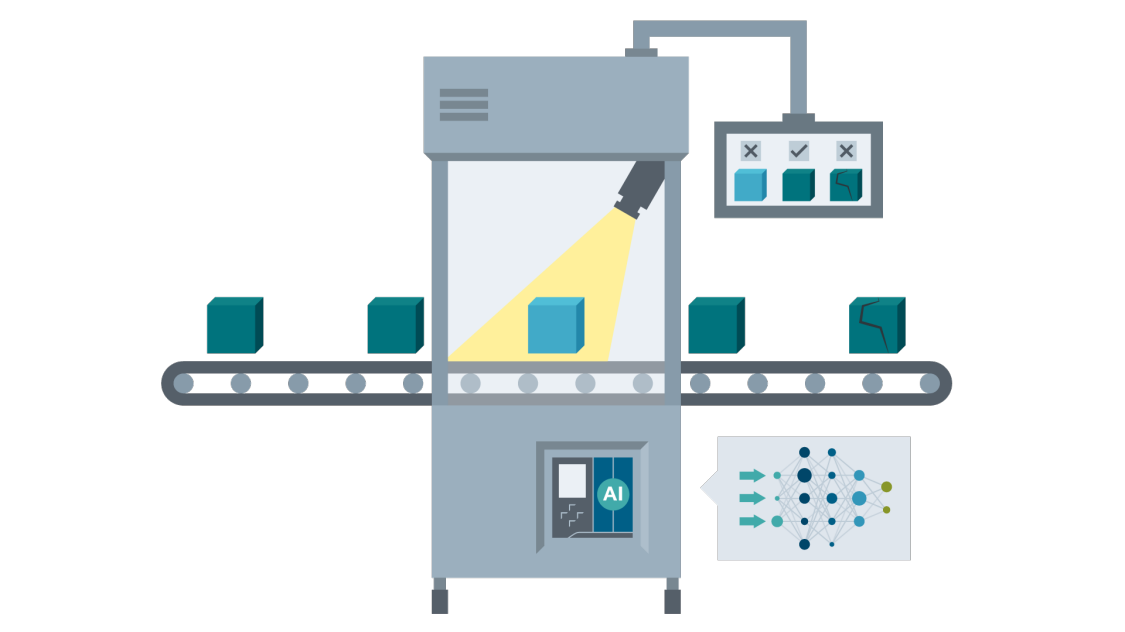

With the rise of deep learning and computer vision, we can automate object detection. We can build deep learning and computer vision models that can detect and locate objects, calculate the distance between them, predict their future stages, etc. Object detection has a wide range of applications in computer vision and machine learning. Object tracking, CCTV surveillance, human activity recognition, and even self-driving cars make use of this technology.

Automation is a very important factor in an industry that manufactures products in mass quantities. After manufacturing the product, the decision to reject or accept is taken by measuring quality parameters. To measure quality parameters such as dimensions and features of manufactured products, inspection is done manually in almost manufacturing industries.

Manual assessment is time consuming, costly, sometimes inaccurate and manual assessment for complicated shapes is very difficult. To overcome these problems quality control and quality management for sensitive industrial product is feasible by use of image processing techniques. In this study use of 2D and 3D image processing is compared to detect edge defects. To extract features of manufactured product from image of product Principal Component Analysis (PCA) is used, defect detection in manufactured industrial products using edge detection methods gives the performance in an acceptable range with them.

We serve all of your needs regarding the face recognition system. Our company, Arya Software, provides the best tool to bring you these systems that can be used in different areas and to provide technical support in this regard. For more information and to see other solutions we provide, you contact us anytime you need.